Process

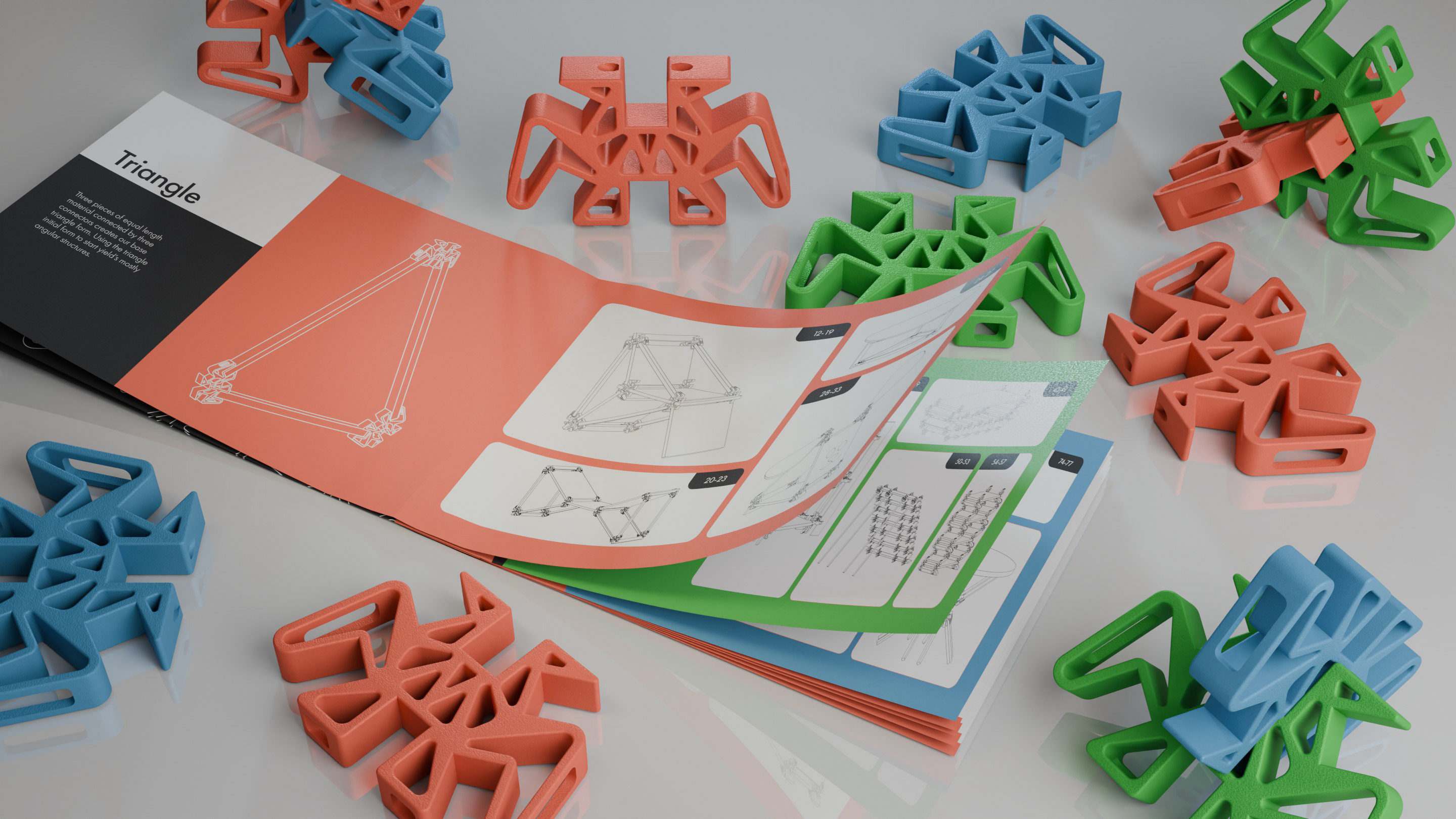

When I first began designing the lamp, I took some time researching lamps created with 3d printing. During this research, I came across a range of lamps that focused on playing with G-code to make interesting shades and shades focusing on the texture of layer lines. The notes I took away from this research were more about how easily you can prototype with 3d printing. As I went into designing my lamp and sketching, my main focus was on creating something that can be expanded easily with modular parts. As the main feature of the lamp, I decided that it should use an aperture to dim itself. My aperture dimming idea came after trying to come up with a unique way for a user to interact with the lamp besides clicking it on and off. The interaction of spinning the shade to dim it seemed so interesting and natural. This would also be a great opportunity to design something more mechanical. So I began sketching out what the lamp may look like assembled and the cross-section.

Rough sketch of the lamp

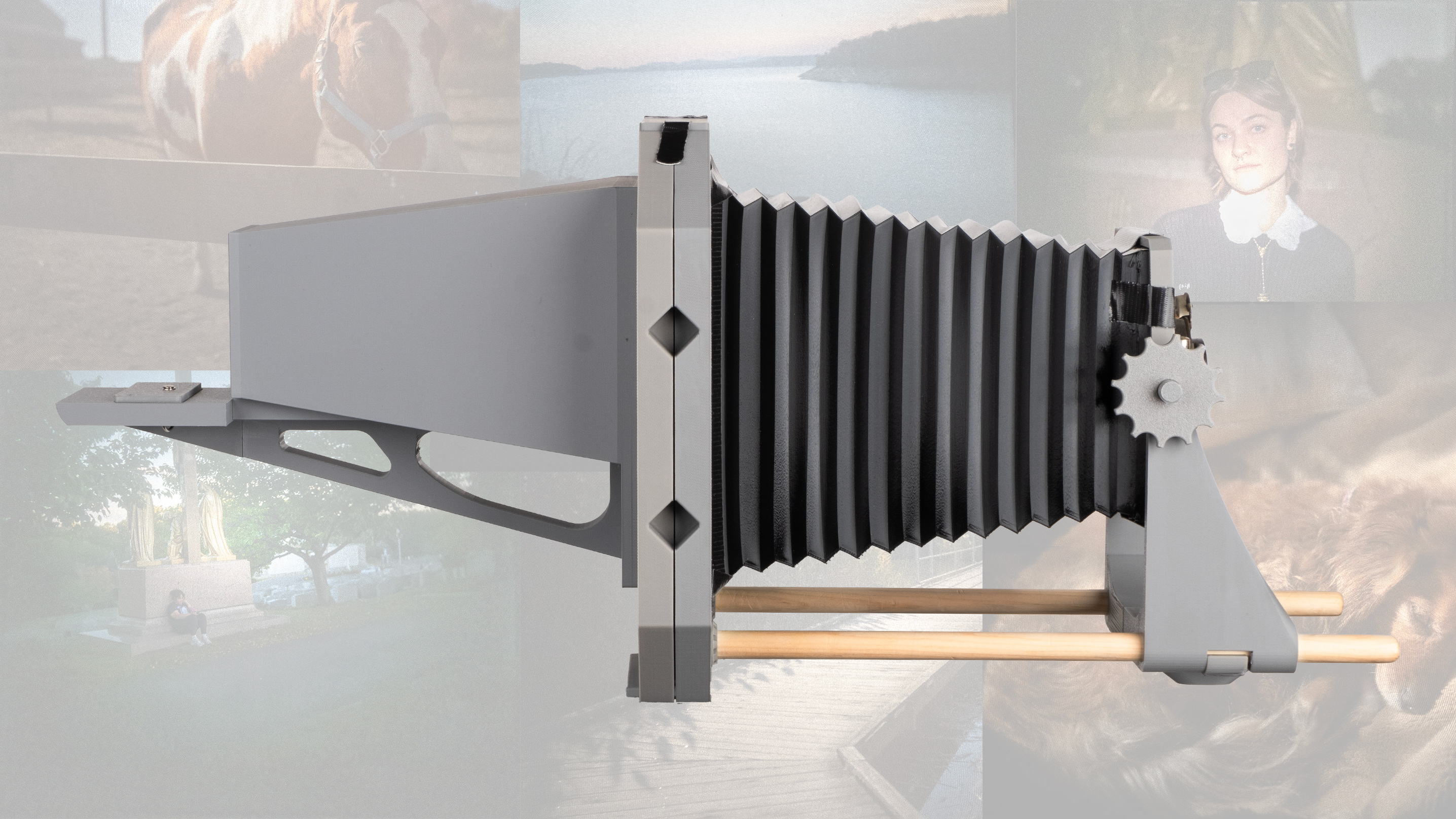

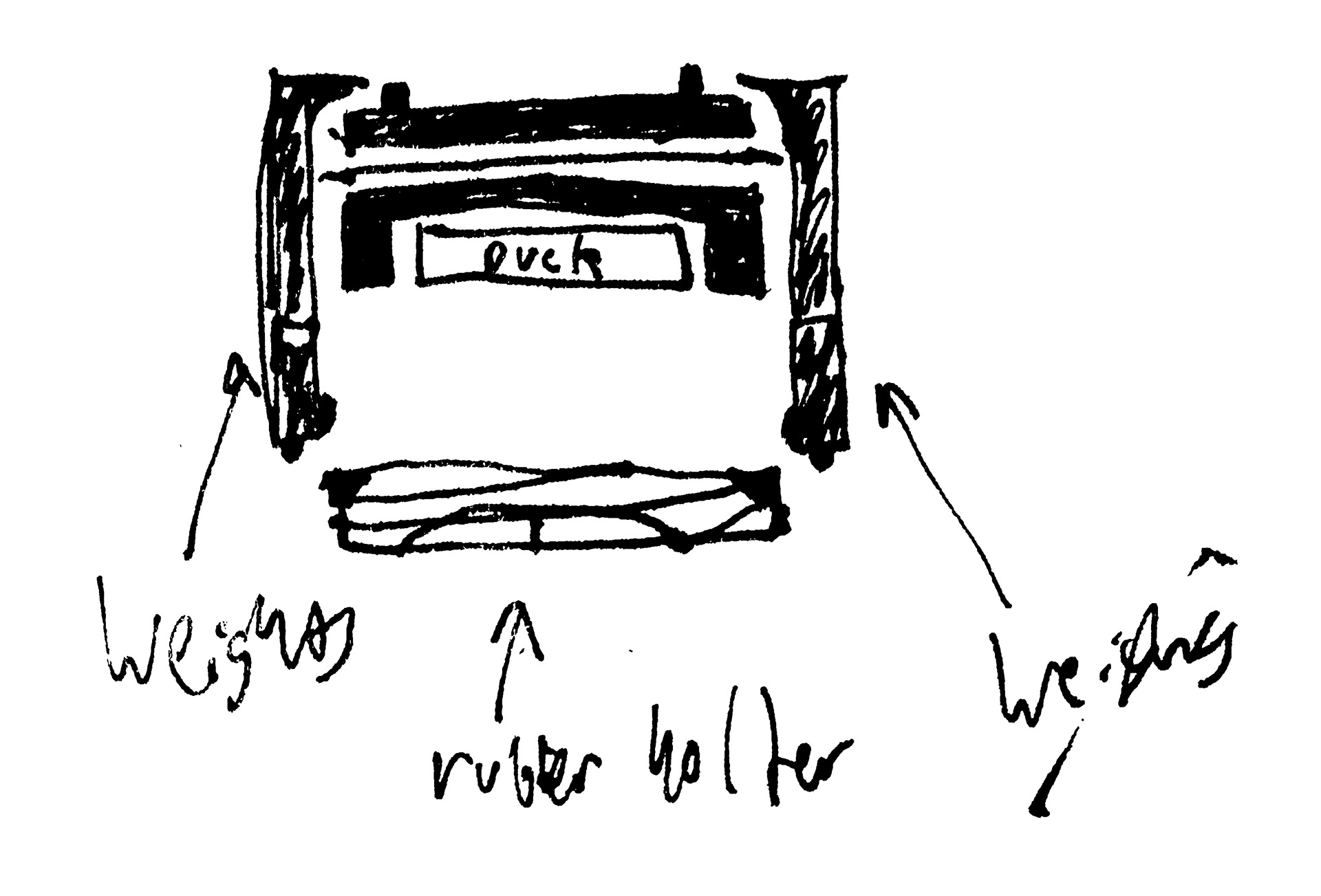

Version one split view of the mechanics

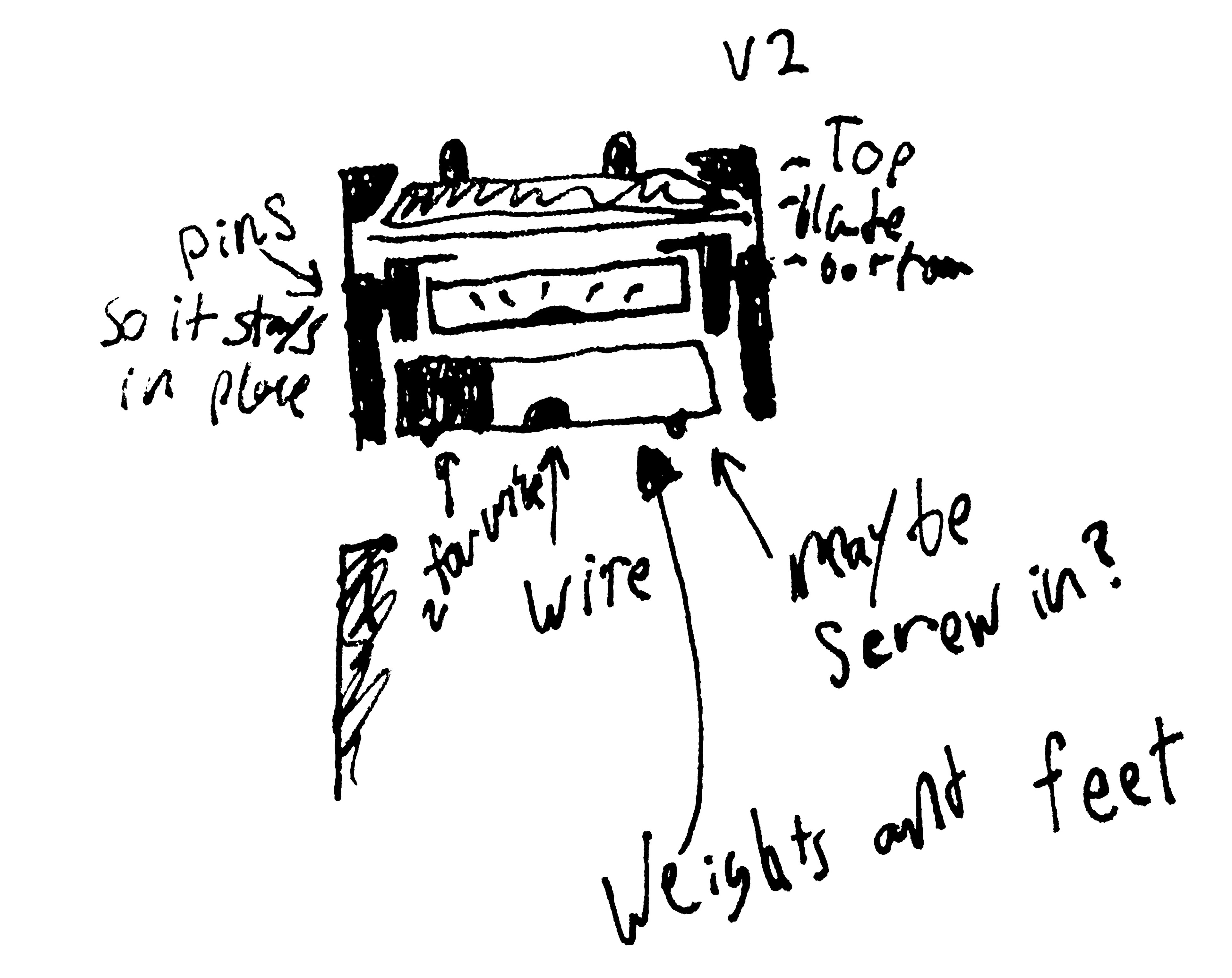

Version two side view of the mechanics

After making my sketches I began working on the apeture itself. Doing some research I found a guide that helped me construct an apteure that met my needs and fit well in what would become the lamp base. After a quick test print and some light adjustments It worked.

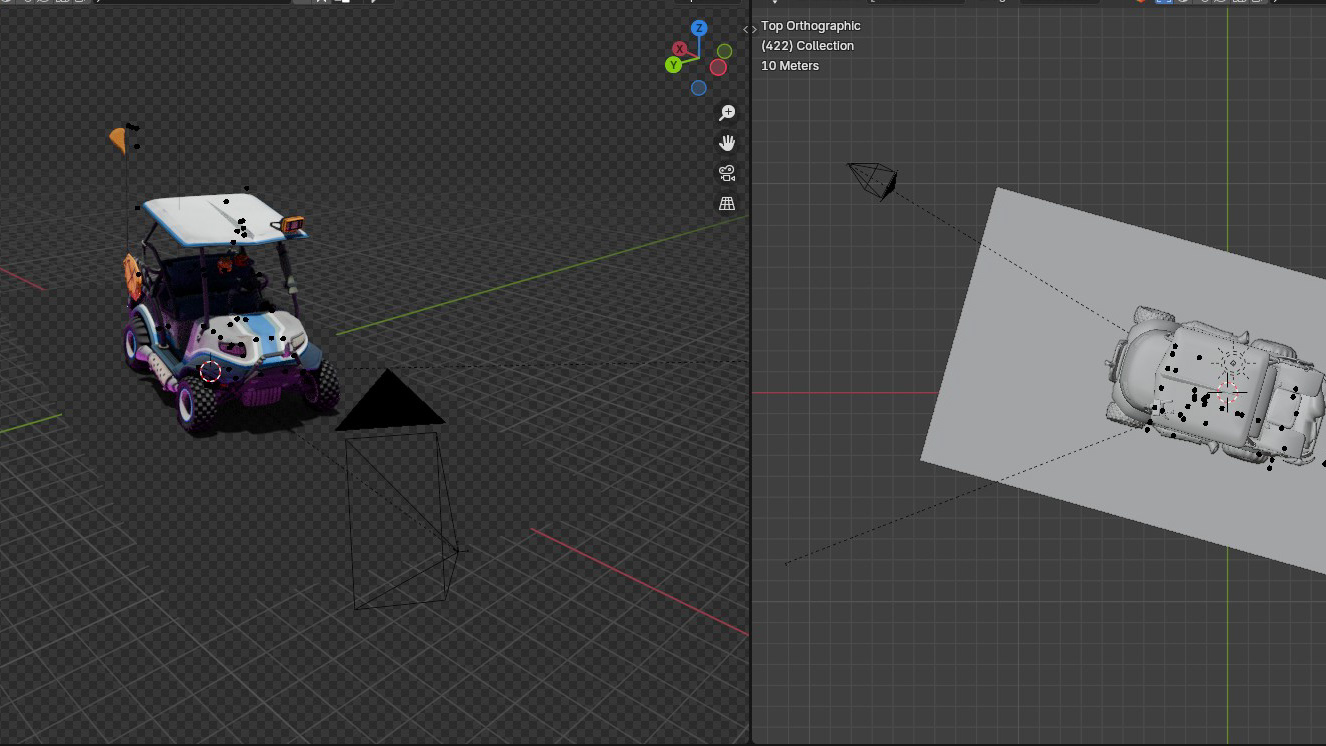

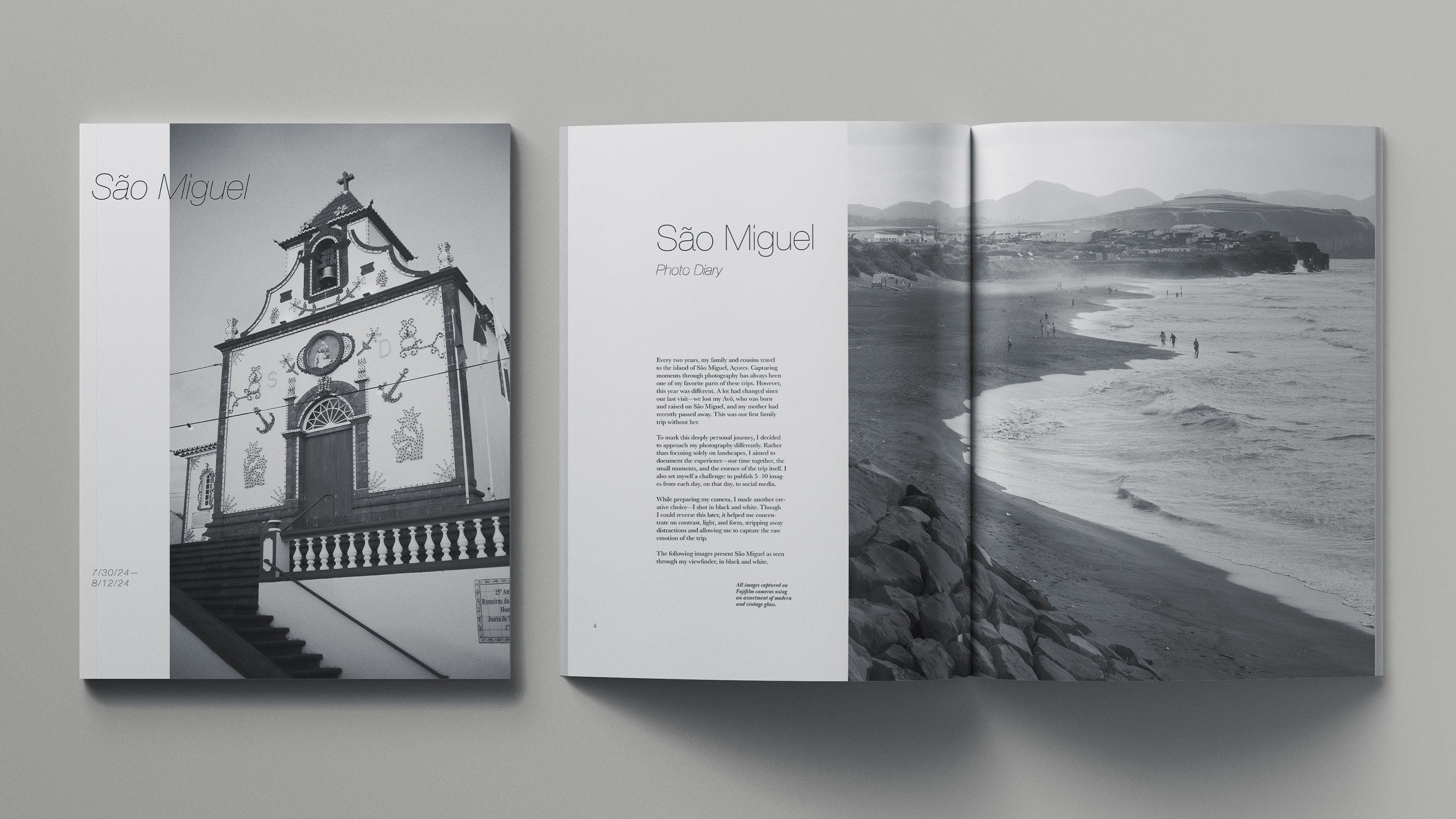

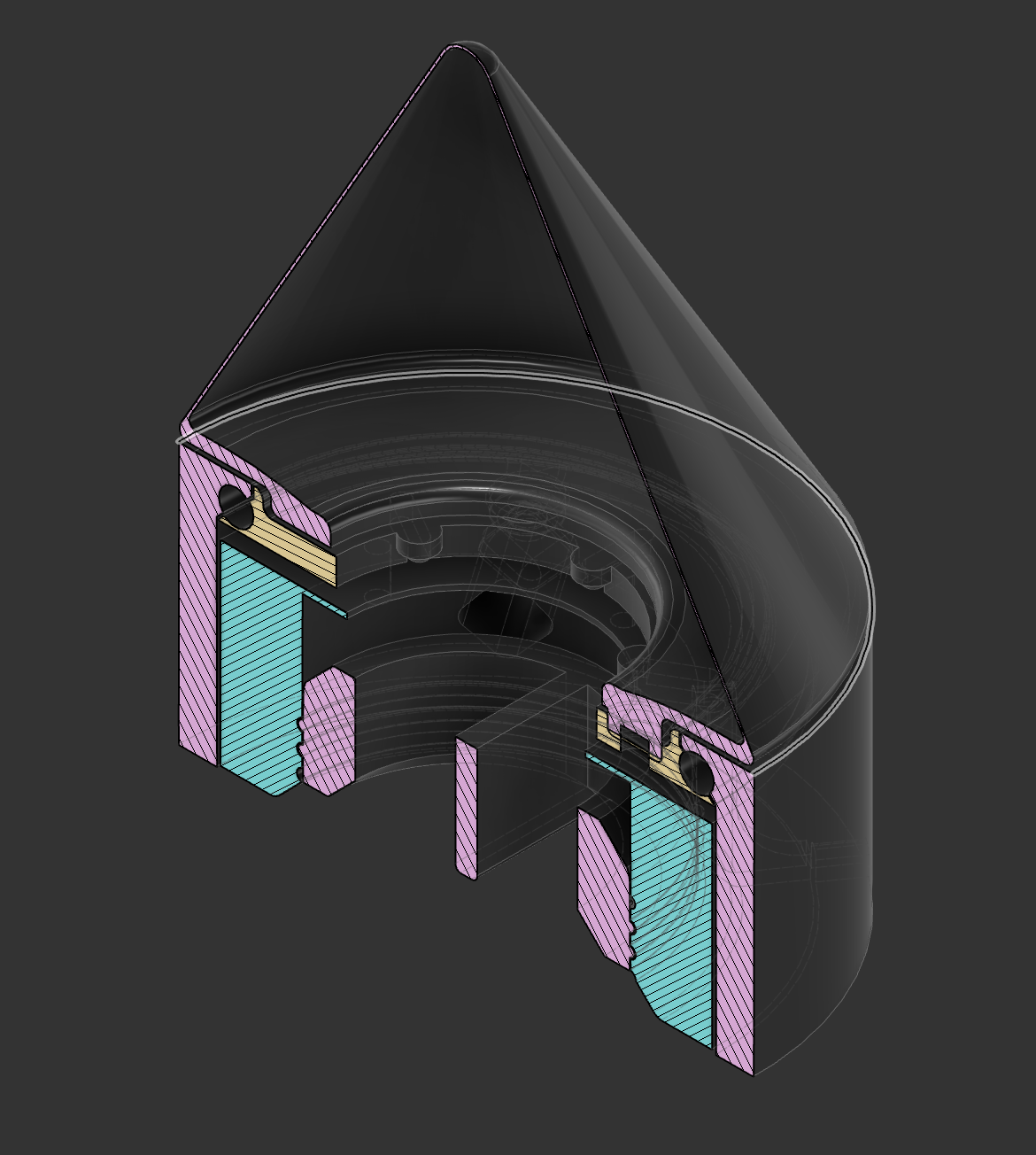

After working on the prototype I began to design the rest of the lamp in Fusion 360. The design is completly modular and allows the user to easily edit the texture of the oustide of the base along with create new shades that snap into the base. When first doing print tests I had to make adjustments as new materials brought on new tolerences. To make the spining of the apeture smoother I decided to add a ball bearing connecting the outer base to the top part of the apeture. The bearing uses 6mm airsoft pellets and snaps into place when constructing the lamp. Below are analysis views of the lamp in Fusion 360.

The final version of the lamp was printed in mostly PLA-CF for the internal parts, Wood PLA for the base, PPA-CF for the blades, and Pearl PLA for the shade.